Toyota Gazoo Racing presents the world premiere of the GR GT and GR GT3

- Two new models which strive to provide the ultimate driving experience by way of enhanced capabilities centred on three key elements: a low centre of gravity, low weight with high rigidity and the pursuit of aerodynamic performance.

- The GR GT is TGR’s new flagship sports car, developed as a road-legal race car that further advances its philosophy of making ever-better motorsport-bred cars.

- The GR GT3 is a new, GR GT-based, FIA GT3-spec race car engineered for customers who want to win races.

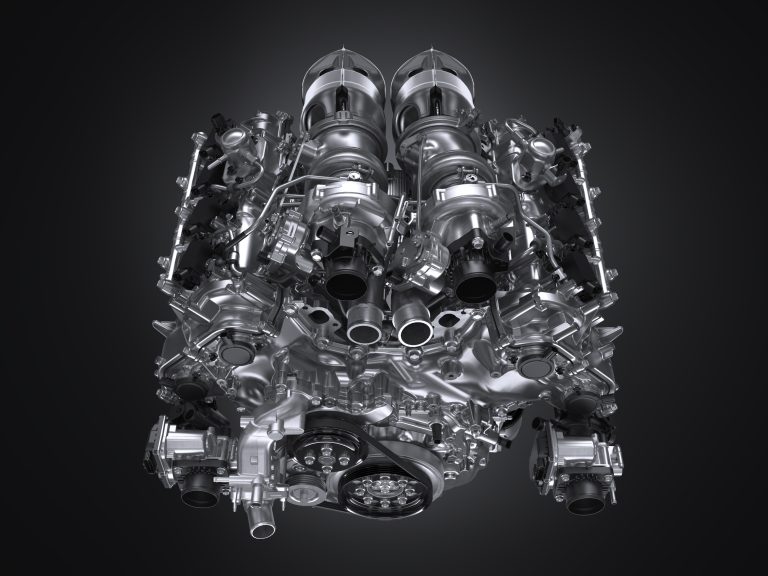

- Both models adopt new technologies and manufacturing methods, including Toyota’s first all-aluminium body frame and a 4.0-litre V8 twin-turbo engine

Toyota Gazoo Racing (TGR) today presented the world premiere of two new models—the GR GT and GR GT3, publicly displaying under-development prototypes for the first time. The GR GT and GR GT3 are flagship models that embody TGR’s philosophy of building ever-better motorsports-bred cars. Their development – starting with the vehicle concept formulation stage – was advanced under a one-team approach centred on TMC Chairman Akio Toyoda, aka Master Driver Morizo, in which professional drivers Hiroaki Ishiura, Tatsuya Kataoka, and Naoya Gamou, gentleman driver Daisuke Toyoda and in-house evaluation drivers worked together with engineers. The GR GT is defined by a driver-first approach to development that involves listening to, understanding and fulfilling the needs of the person behind the wheel. The GR GT3 – a race car based on the GR GT – was also developed with this methodology.

The GR GT and GR GT3 are positioned as flagships in the footsteps of the Toyota 2000GT of the 1960s and the Lexus LFA. One of the development goals was to preserve and pass on “the secret sauce of car-making” to the next generation following Toyota’s Shikinen Sengu* principle. The two models are the result of the veterans who developed the Lexus LFA passing on their skills and techniques to a younger generation of members; the active adoption of new, Toyota-first technologies for enhanced vehicle performance; and the taking on of numerous and unprecedented challenges.

Three key elements

The GR GT was conceptualised and developed as a road-legal race car. Demonstrating the commitment to a driver-first approach, development strived to not only endow the car with a high level of dynamic performance but also to achieve a sense of car-driver unity, enabling the driver to interact with their vehicle at all times. The GR GT is equipped with a hybrid system that pairs a new 4.0-litre V8 twin-turbo engine and a single electric motor. In addition to maximum system output of 641bhp (650 DIN hp/478kW) or greater and maximum system torque of 850Nm or greater (development target values) for exceptional performance, an unrelenting focus was placed on three key elements: a low centre of gravity, low weight with high rigidity and the pursuit of aerodynamic performance.

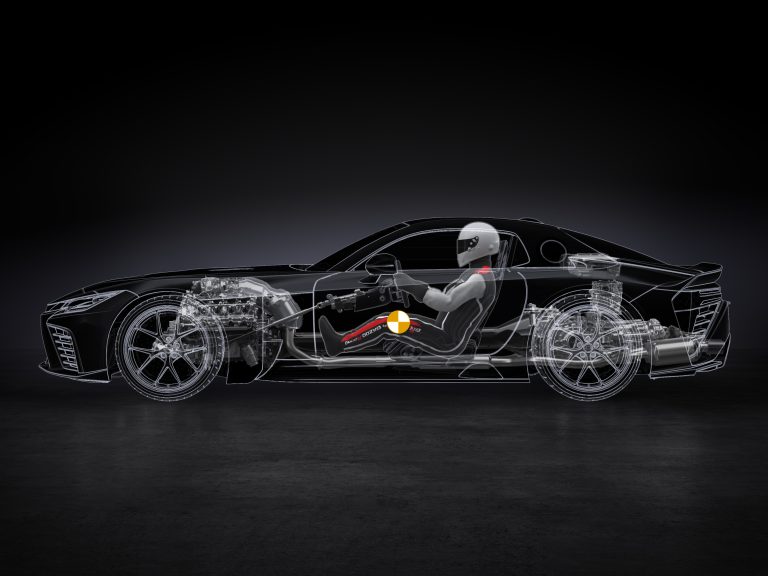

Vehicle packaging for an ultimate low centre of gravity

Development of the GR GT, which is ongoing, began with the aim of achieving an exceptionally low centre of gravity by considering how to lower both overall vehicle height and the driver’s position as much as possible. Attention was then paid to adopting a front-engine, rear-wheel-drive powertrain layout for ease of handling when driving the vehicle to its limit. Optimised positioning of heavy components, such as the engine, rear-mounted transaxle, and other major mechanisms, significantly lowered their centre of gravity. Furthermore, the centres of gravity of both driver and car have been made roughly identical by pursuit of an ideal driving position that enhances the sense of car-driver unity and ease of handling.

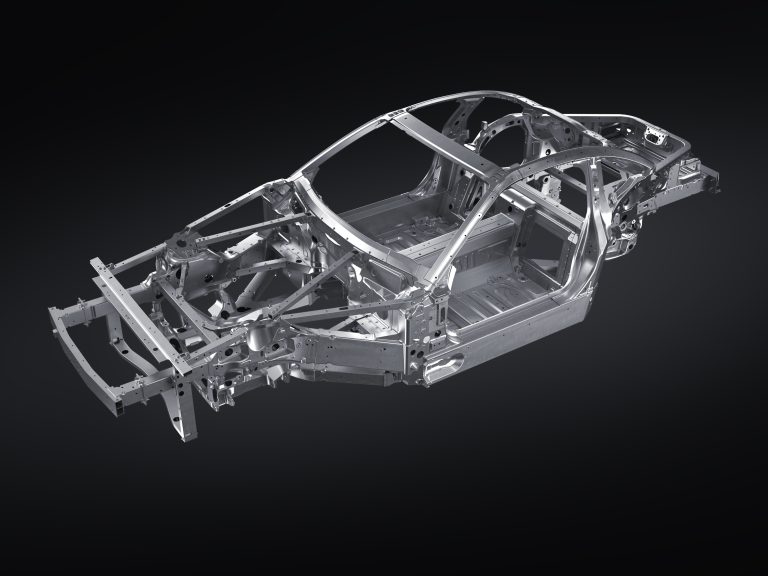

Adoption of Toyota’s first all-aluminium body frame

The key element of low weight with high rigidity is addressed by the GR GT using Toyota’s first all-aluminium body frame. Using carbon fibre reinforced plastic (CFRP) and other materials in the panels has produced a strong yet light body.

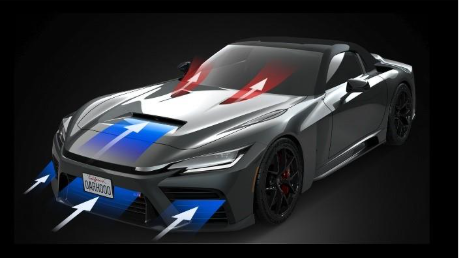

A Reverse approach to create styling that pursues aerodynamic performance

GR GT (prototype)

The process to create exterior styling in pursuit of aerodynamic performance was distinct from that previously used in Toyota car-making. Conventionally, attention is turned to aerodynamics once exterior styling has been finalised; in the case of the GR GT, ideal aero performance was established first. Aerodynamics engineers and exterior designers worked together to achieve styling that supports aerodynamic and cooling performance.

Interior styling was also crafted meticulously and without compromise, based on ergonomics aimed at achieving the optimal driving position from a professional driver’s perspective and the visibility needed for on-the-limit driving. Naturally, in addition to circuit driving, care has been taken to ensure suitability for everyday use.

Aimed at being an FIA GT3-spec race car chosen by people who want to win GR GT3 (prototype)

The GR GT3 features the same three elements of a low centre of gravity, low weight with high rigidity and the pursuit of aerodynamic performance found in the GR GT, on which it is based. It meets the specifications of the Federation Internationale d’Automobile (FIA) GT3, the top category of production vehicle-based customer motorsports, and aims to be a car chosen by people who want to win, yet easy to drive for anyone.

TGR believes that its driver-first principle is just as important in GT3 race car category as it is for the GR GT, as both professional and gentleman drivers will be behind the wheel. At the same time, as well as raising the competitiveness of the GR GT3 as a car, TGR is also preparing to establish an support service for customers who race to help them fully enjoy their motorsports experience.

Making ever-better cars

The TGR flagship models GR GT and GR GT3 are defined not only by their adoption of new technologies but also by having been created using new development and manufacturing methods. In developing the GR GT and GR GT3, TGR employed multiple methodologies that leverage insights gained from competing in motorsports. The use of driving simulator-assisted vehicle research and development, which is now common in race car development, is an example of this. Introducing driving simulator use early in the development process enabled fundamental vehicle characteristics to be efficiently refined from the outset. As well as using simulators in the creation of each component, extensive real-world testing was undertaken not only on test courses, such as at Toyota Technical Center Shimoyama, but also at circuits around the world, including Fuji Speedway and the Nürburgring, enabling verification of at-the-limit driving performance and durability. GT GR testing also took place on public roads to ensure the car can provide exhilaration, ease of handling, and peace of mind in everyday use.

Like other GR models, the GR GT and GR GT3 have been repeatedly honed, driven to failure, and repaired to make them into models that will live up to all drivers’ expectations. As it accelerates its efforts to make ever-better cars, TGR is continuing development of the GR GT and GR GT3 toward launching them around 2027. Further details will be released as they become available.

GR GT main specifications (prototype development targets, in-house measurements)

| Body | Length (mm) | 4,820 | |

| Width (mm) | 2,000 | ||

| Height (mm) | 1,195 | ||

| Wheelbase (mm) | 2,725 | ||

| Body structure, cabin | Frame | All-aluminium body frame | |

| Occupancy | 2 | ||

| Vehicle weight | Vehicle weight (kg) | 1,750 or lower | |

| Front-rear weight distribution | Front: 45; rear: 55 | ||

| Powertrain | Engine displacement | 3,998 cc | |

| Engine bore x stroke (mm) | 87.5 × 83.1 | ||

| Engine type | V8 | ||

| Turbocharger | Twin-turbo | ||

| Electric motor | Transaxle-integrated single-motor hybrid | ||

| Transmission | 8-speed automatic | ||

| Maximum system output (bhp/DIN hp/kW) | 641/650/478 or greater | ||

| Maximum system torque (Nm) | 850 or greater | ||

| Driving equipment, suspension & related items | Drivetrain | Front engine, rear-wheel drive | |

| Suspension | Front | Double wishbone with coil spring | |

| Rear | Double wishbone with coil spring | ||

| Brakes | Front | Carbon ceramic disc brake | |

| Rear | Carbon ceramic disc brake | ||

| Tyre size | Front: 265/35ZR20; rear: 325/30ZR20 | ||

| Other | Top speed (mph, km/h) | 199/320 or greater | |

GR GT3 main specifications (prototype development targets, in-house measurements)

| Body | Length (mm) | 4,785 |

| Width (mm) | 2,050 | |

| Height (mm) | 1,090 | |

| Powertrain | Engine displacement (cc) | 3,998 |

| Engine type | V8 | |

| Turbocharger | Twin-turbo | |

| Driving equipment | Drivetrain | Front engine, rear-wheel drive |

As the GR GT and GR GT3 announced today are still under development, various details may be subject to change without notice.

Exterior styling for aerodynamic and cooling performance

The GR GT’s styling was developed under an “aerodynamics first” concept in which aerodynamics engineers and exterior designers worked as a single team. With the GR GT boasting a top speed in excess of 199mph (320km/h), aerodynamic performance was one of the most vital concerns. As the GR GT is envisioned as a road-legal race car, the conventional production vehicle development process of considering aerodynamic efficiency and cooling performance after the exterior styling has been set needed to be rethought. Aerodynamics engineers experienced in FIA WEC competition vehicle development joined the GR GT development team and engaged in thorough discussions with vehicle designers. This led to overall vehicle packaging being based on an “aerodynamic model” representing the aerodynamic design team’s proposal for the ideal form. It was only after this that the exterior designers prepared design sketches with mass production in mind, eventually leading to finalisation of vehicle styling in a process that was the reverse of the normal approach.

Interior styling that prioritises functionality and operability

The GR GT’s interior styling centred on prioritising the driving position and visibility above all else to achieve an optimal design that would be suitable for both professional and gentleman drivers, as well as for both circuit and daily use.

Pursuit of the ideal driving position, coupled with consideration of interior styling, renewed awareness of the importance of sufficient visibility, as well as a sense of being protected. Particular attention was paid to excellent operability, with driving-related switches placed near the steering wheel and positioned and shaped for intuitive operation.

For ease of visual recognition, even during circuit driving, special attention was paid to the gauges, with the width, height and position of information displays, such as the shift-up and gear selection indicators, determined through a process of trial and error.

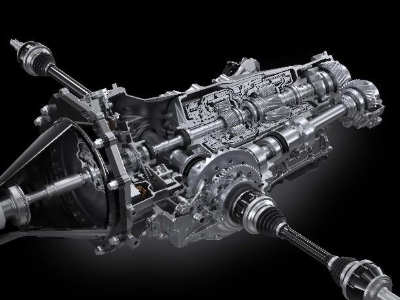

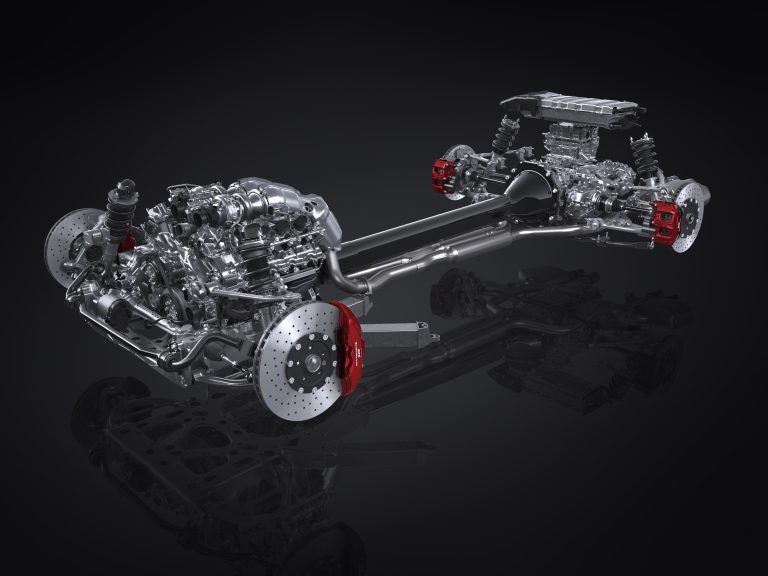

New 4.0-litre, V8 twin-turbo engine and rear transaxle

The GR GT’s 4.0-litre, V8 twin-turbo engine, the first to be fitted in a TMC production vehicle, was developed on a “thoroughly compact and light” design concept to help achieve the GR GT’s “packaging of low overall height and a low centre of gravity”. The engine has an 87.5 x 83.1 bore and stroke, the short stroke reducing overall engine height. The hot V configuration positions a turbo in each engine bank. The unit also features dry-sump lubrication and an oil pan with a thinner than usual design.

The engine’s power is transmitted to the rear transaxle via a CFRP torque tube. In addition to a motor-generator, the transaxle integrates a new eight-speed automatic transmission, which uses a wet-start clutch in place of a torque converter, and a mechanical limited-slip differential. The motor-generator, which is positioned in front of the transmission, is used to help make up for the momentary lag in torque response that occurs during acceleration and gear changes. While providing a direct feel that surpasses that of the Gazoo Racing Direct Automatic Transmission used in the GR Yaris and GR Corolla, the GR GT’s eight-speed automatic transmission is being developed with the aim of achieving world-class shift speed, as well as shift control that allows shift manipulation at will, even when in D-range automatic shift mode. To minimise the wheelbase in consideration of the overall vehicle packaging, the rear transaxle, after relaying the power that has been conveyed from the engine and through the electric motor and automatic transmission to its far end, uses a conical gear to reverse the direction of that power. This then turns the driveshaft through the mechanical limited-slip differential. This structure is unique among front-engine, rear-wheel-drive vehicles and represents the optimisation of the mechanism used in all-wheel-drive vehicles for use in the GR GT.

For exceptional performance, the development target for maximum system output is 641bhp (650 DIN hp/478kW) or greater, and the development target for maximum system torque is 850Nm or greater. Also, the adoption of a rear transaxle and the optimal placement of the drive battery, fuel tank, and other heavy components have resulted in a 45:55 front-to-rear weight distribution, contributing to ease of vehicle handling.

Powertrain development involved advancing studies through the use of race development driving simulators and system benches onto which entire powertrain systems could be mounted. Consideration was also given to thermal management, mounting position and serviceability. To ensure continued sales, development is being undertaken to comply with increasingly stringent emissions regulations. The GR GT3 also uses a 4.0-litre V8 twin-turbo engine with many structural components shared with those in the GR GT.

An enjoyable sound at all times, from engine start to acceleration and deceleration

The GR GT delivers not only high-level performance but also the distinctive racing sound of a V8 twin-turbo engine. Sound development centred on two pillars: creating sound that enables interaction with the car and sound that conveys changes in thermal energy. The structure of the exhaust pipe has been meticulously crafted to produce sound that synchronises with the state of the vehicle.

An all-aluminium body frame and a chassis that prioritises ease of at-the-limit handling

The mainstay of the GR GT’s low weight with high rigidity is Toyota’s first all-aluminium body frame. A high level of rigidity has been achieved by positioning large aluminium castings in the frame’s main structure, as well as through optimal placement of aluminium extrusions and other components, and the use of advanced joining technologies. Additionally, the model’s body panels are made of aluminium and CFRP.

The suspension features a new, low-mounted double-wishbone system front and rear with forged aluminium arms. Its characteristics were developed from scratch, with a focus on linear response and a high level of controllability, from everyday use to at-the-limit driving.

The tyres are Michelin Pilot Sport Cup 2, developed exclusively for the GR GT. Since the early stages of development, the design of both the suspension and the tyres has involved working with professional drivers in the use of simulators and conducting test runs and simulator evaluations in pursuit of optimal performance so the driver can interact seamlessly with the car on circuits, as well as on winding roads and other public highways.

Brembo carbon brake discs are used, and vehicle behaviour control during braking was developed together with professional drivers. The GR GT’s Vehicle Stability Control system allows multi-stage adjustment of driving force and braking control, enabling driver selection of the vehicle control difficulty level based on driving skill and weather conditions, for an enjoyable and secure driving experience. This setup is also used in TGR’s Nürburgring 24-hour endurance race vehicles and is an example of technology honed through competing in motorsports.

Additionally, the basic structures of the aluminium space-frame chassis and double-wishbone suspension system have been developed so that many of their components can be shared with the GR GT3.

*A ritual in which a Shinto shrine is periodically rebuilt

ENDS