Toyota FCV-R Fuel Cell Concept: Revolution and Reality

- Toyota’s next step towards mass-produced hydrogen fuelled vehicles

- Innovative packaging in a mid-size family saloon

- Latest interpretation of Toyota’s design language and styling

- Next-generation multimedia system with smartphone-style icon display and 3D navigation mapping

- Toyota’s first commercially available hydrogen vehicle due on sale in 2015

Toyota believes that when it comes to the development of future powertrains to deliver sustainable mobility, one size does not fit all requirements.

Different powertrain needs and solutions are determined not only by vehicle size and travel distance, but also by regional variations in energy availability, infrastructure and regulations.

As hybrid, plug-in hybrid, electric and fuel cell vehicles replace most of today’s conventional cars; each will meet different principle criteria. Electric vehicles will be used for short-distance travel and fuel cell vehicles for middle to long-distance journeys.

Toyota’s Hybrid Synergy Drive technology has been specifically designed to be future-proof, and is readily adaptable for use in Plug-in Hybrid Vehicles (PHEV), Electric vehicles (EV) and Fuel Cell Vehicles (FCV), reinforcing the company’s lead in the drive towards sustainable mobility.

The significance of fuel cell technology

Toyota believes that the FCV is the closest technology yet to achieving the ultimate eco-car, with hydrogen as an ideal, ultra-clean source of energy.

A fuel cell structure comprises electrodes and polyelectrolyte films sandwiched between separators, and produces electricity through a chemical reaction between hydrogen (stored in the vehicle) and oxygen (from the air). When hundreds of cells are stacked together, the results is a fuel cell (FC) stack.

A fuel cell is outstandingly energy-efficient, generating no CO2, NOx or PM, with water vapour as the only emission. In theory it can covert as much as 83 per cent of hydrogen’s energy into electric power, about twice the efficiency possible with current petrol and diesel engines.

Not only does a hydrogen fuel cell powertrain’s extreme efficiency save energy and drive down costs, it also delivers a quiet, smooth driving experience with the bare minimum of noise, vibration or harshness. Further benefits are a long driving range and a refuelling process that is as quick as that of a conventionally powered vehicle.

Key challenge: the hydrogen infrastructure

Hydrogen offers future global energy security, capable of being made from a wide variety of raw materials, from petroleum and natural gas to biomass. It can also be produced through the electrolysis of water. Carrying out electrolysis using electricity generated from natural energy sources, such as solar, wind or hydro-power, enables hydrogen production without generating significant CO2 emissions at the same time.

Nonetheless, a smooth shift to a hydrogen-based society will be a major undertaking. Reaching consensus on what hydrogen should be made from, how to deliver it and how to build a fuelling infrastructure depends on all sectors of society working together, including governments.

To that end, and in anticipation of the commercialisation of a number of FCVs, Toyota and other manufacturers signed a letter of understanding in September 2009 calling for oil and energy companies and government organisations to co-operate in the creation of hydrogen infrastructure networks of sufficient density in Europe, Japan, Korea and the United States in 2015.

A hydrogen infrastructure has already begun to emerge. It is sufficiently well developed to allow Toyota to road test and build the profile of hydrogen fuel cells as a viable powertrain.

Toyota’s 20-year history of fuel cell development

Toyota began work on FCVs in 1992, developing its hydrogen fuel cells and high-pressure storage tanks in-house. The company applies its Hybrid Synergy Drive technology to FCV development, replacing petrol engines with fuel cells and petrol fuel tanks with high pressure hydrogen tanks. The Toyota FC stack is a performance leader in fuel cell technology.

Toyota demonstrated its first Fuel Cell Electric Vehicle in 1996 and every year since then it has improved the technology and extended its capabilities to increase performance, driving range and commercial viability.

In 2002 Toyota developed the world’s first Fuel Cell Hybrid Vehicle for limited lease, and the first FC bus certified by the Japanese government. In the past decade the company has continued to work on residential fuel cell development, put fuel cell buses on the road and, in 2008, launched the FCHV-adv.

The Toyota FCHV-adv achieved a 25 per cent improvement in fuel efficiency vs. Toyota’s original Fuel Cell Electric Vehicle and, by using a Toyota-developed 70MPa high-pressure hydrogen tanks, had a cruising range of about 515 miles on a single fill-up – more than twice that of its predecessor. Furthermore, the FCHV-adv could operate in -30°C, marking a great improvement in its cold weather performance.

Fuel cell technology development challenges and testing

Toyota is already overcoming some of the historical barriers to the creation of marketable fuel cell vehicles. This includes closing in on its goal of offering a driving comparable to conventional powertrains and performance at temperatures down to -35°C.

Following further fine-tuning and technological development, Toyota will introduce an affordable saloon-type FCV which matches the performance of a conventional combustion engine vehicle in Japan, the US and Europe by 2015.

In addition, Toyota is preparing to be able to supply tens of thousands of vehicles annually in the 2020s when FCVs are expected to achieve full, mass-market commercialisation. This market growth will be boosted by the further roll-out of FCV technology, the increased availability of hydrogen refuelling stations and the reduction in costs which accompanies a maturing technology.

The FCV-R concept: futuristic styling and advanced infotainment

Through the fusion of advanced technology, smart thinking and intelligent packaging, the FCV-R combines breakthrough innovation with ergonomic practicality and futuristic styling.

Incorporating elements from the current Toyota family design, the front and rear styling displays a ‘W’ motif, symbolising the fuel cell cooling system. This creates a sleek, aerodynamically efficient cabin silhouette and an individual road presence.

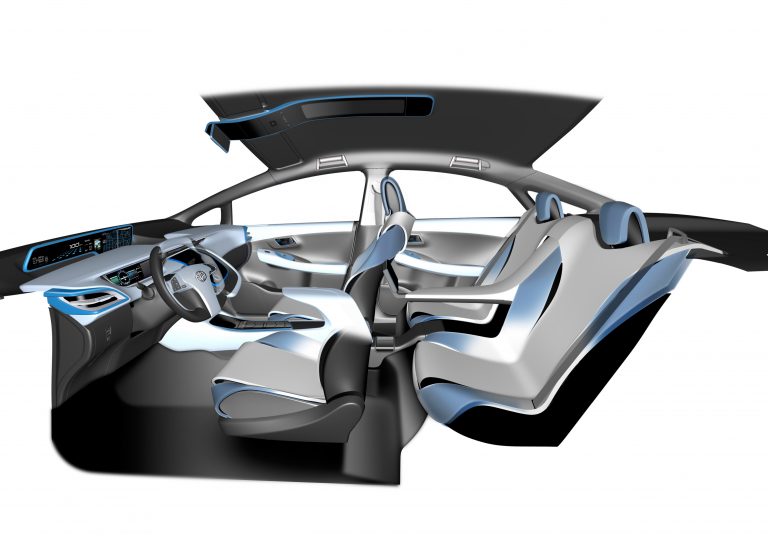

The interior displays crisp detailing, with a twin-screen mounted on the centre console that is an evolution of Toyota Touch, giving easy access to the main infotainment controls. The lower, icon display screen is for control of the navigation, audio and air conditioning. The upper screen, positioned in the driver’s line of sight displays the most relevant driver information, including the navigation map and guidance in 3D.

The system is designed for easy connection to a smartphone, both replicating phone applications on the vehicle’s display screen and relaying vehicle information to the phone.

Much of the smart thinking behind the FCV-R can be seen in the interior packaging. The vehicle is just 4,745mm long, 1,510mm high and 1,790mm wide. The fuel cell stack is smaller than in previous FCVs, and sits under the seats, along with twin hydrogen tanks.

The combined volume of the fuel tanks gives the FCV-R a driving range of around 435 miles, while generating no CO2, NOx or PM and water vapour being the only emission. The location of the tanks and stack beneath the vehicle floor means that cabin and luggage space can be maximised to the make the vehicle and eminently practical family car.

ENDS