Toyota Taps Landfill Waste For Green Power

Toyota is “turning garbage into good” with a scheme to use gas from a landfill site to power vehicle production.

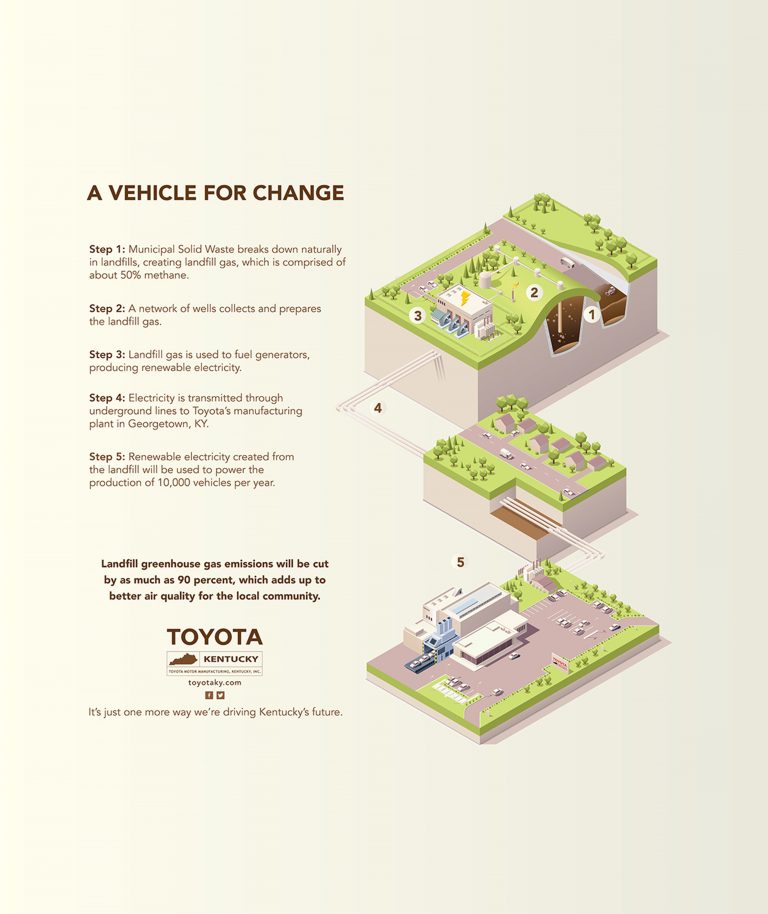

Although the company targets zero waste-to-landfill for its operations, it has come up with a method of generating “green” electricity from a disposal site close to its factory in Georgetown, Kentucky. The system is expected to be up and running early in 2015, producing enough power to build around 10,000 vehicles a year – including some of the world’s most environmentally efficient hybrids.

Toyota is working with Waste Services of the Bluegrass to collect the gas, which is created as the solid landfill waste breaks down. It is captured in a network of wells and used to fuel electricity generators. The power is then fed by underground lines to the Toyota plant a few miles away.

When working at full capacity, the system will generate one megawatt of electricity an hour, approximately enough to power 800 average American homes. At the same time, greenhouse gas emissions from the landfill site will be cut by as much as 90 per cent, improving local air quality

This is a further example of the smart approach to cleaner, sustainable energy sources that is being applied at Toyota manufacturing sites worldwide, including in the UK where the Burnaston car plant has installed one of the country’s largest industrial solar arrays. Constructed in a joint project with British Gas, the arrangement of around 17,000 solar panels spreads across an area of 90,000m2 within the industrial site, and is capable of producing 4.6 million kWh of electricity a year – enough power to build 7,000 cars a year. It also cuts annual CO2 emissions from the factory by around 2.000 tonnes.

Toyota Manufacturing UK was one of the first European Toyota production operations to eliminate waste to landfill, back in 2002. Six years later it also achieved zero waste incineration. Likewise Toyota Motor Manufacturing Kentucky sends no waste to landfill, implementing a thorough recycling programme that includes producing compost used to help fertilise a garden on site. Already this has yielded more than half a tonne of produce, which the company has donated to local foodbanks.