Toyota Targets Cleaner Factories with Trial of New Fuel Cell Hybrid Power Generation System

Toyota’s new hydrogen fuel cell and hybrid power technologies are not just putting cleaner cars on the roads, they are also being developed as a potential low emissions power source for manufacturing. A trial has just got under way at the Motomachi vehicle factory in Japan to test and evaluate a new internal hybrid power generating system that will help Toyota in its progress towards eliminating CO2 emissions from all its plants, a key target in the Toyota Environmental Challenge 2050.

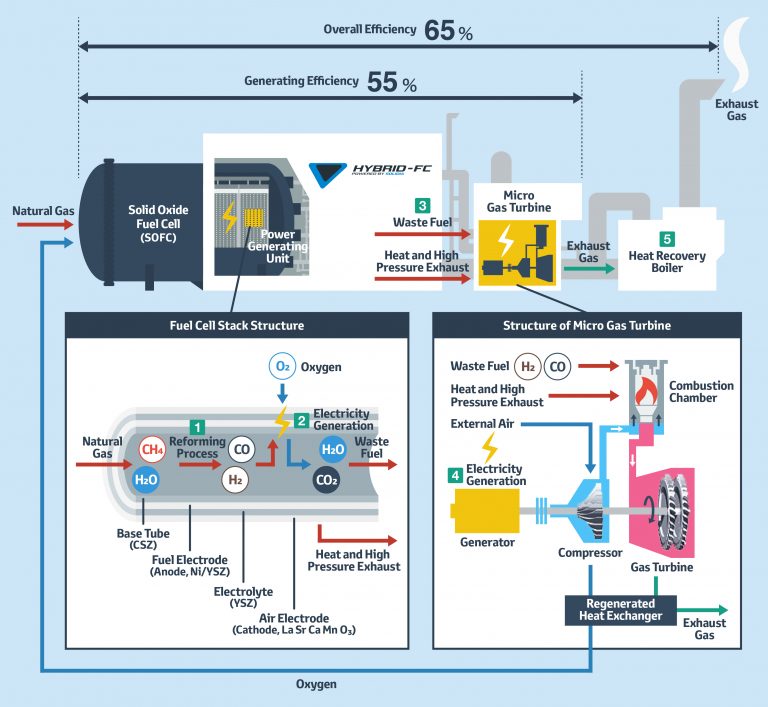

The hybrid power generation system features solid oxide fuel cells (SOFCs)1 and micro gas turbines and uses hydrogen and carbon monoxide, obtained by reforming natural gas. Fuel cell technology and a micro gas turbine are used in a two-stage power generation mechanism with a 250kW output. It also features a co-generation system (combined heat and power) that makes use of any waste heat produced in the power generation process.

High generating efficiency (55 per cent2) is achieved and the co-generation facility increases overall efficiency (65 per cent). This has prompted Toyota to position it as an effective technology that can help realise its goal of building a low carbon society. All the electricity and any waste heat produced by the system is used within the Motomachi plant.

The hybrid power generation system is an initiative introduced as part of technological demonstration by the New Energy and Industrial Technology Development Organisation (NEDO) in Japan. It has been jointly developed by Toyota, its subsidiary Toyota Turbine and Systems, and Mitsubishi Hitachi Power Systems. The Motomachi trial has been designed to test and evaluate the system’s energy efficiency, performance and durability.

Toyota will continue to promote the development and introduction of efficient use of hydrogen technology in factories, while continuously monitoring the results of the hybrid power generation system.

1 SOFCs use ion conductive ceramic as an electrolyte, allowing for operating temperatures from 700 to 1,000°C.

2 Equivalent to the amount of electricity remaining after power used in the station (for operation of equipment used in power generation) is subtracted from the amount of power generated.

Fuel cell comparisons for reference

| Solid Oxide Fuel Cell | Polymer Electrolyte Fuel Cell | |

| Operating temperatures | High (700°C-1,000°C) | Low (70°C-90°C) |

| Application | Wide range of uses, from small-scale (household) to large-scale (plant power supply) | Suitable for small-scale use (household, vehicle power supply) |

| Characteristics | High generating efficiency

Platinum no required as a catalyst | Low operating temperature

Ease of start-up and shut-down |

Technical overview of the hybrid power generation system

- Natural gas (CH4) is reformed within the fuel cell and hydrogen (H2) and carbon monoxide (CO) are extracted.

- Electricity is generated in the fuel cell through a chemical reaction that occurs between the hydrogen and carbon monoxide with the oxygen (O2) contained in the compressed air delivered by the micro gas turbine.

- Waste fuel that is unused in the fuelled power generation (H2 and CO) is delivered to the micro gas turbines with the heat and high pressure exhaust producing during power generation.

- The waste fuel is burned in the micro gas turbines; electricity is generated as the turbine rotates.

- Waste heat is collected from the exhaust gas produced during the burning process.