Toyota World-First Technique Supports R&D for Longer Battery Life and Extended Driving Range for Electric Vehicles

A longer battery life and an extended driving range on a full charge are key factors in making electric vehicles (EVs) a practical and attractive proposition for motorists looking to switch to cleaner, alternative fuels. Toyota has produced a world-first technique1 that can help in the research and development of future lithium-ion batteries that better meet these requirements.

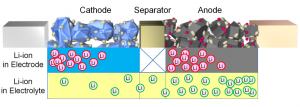

It has produced a technical method for observing how lithium ions behave in an electrolyte in a lithium-ion battery (like that used in the Toyota Prius+ and Prius Plug-in Hybrid), both when the battery is being charged and discharging power. It allows real-time observation of the deviation of lithium (Li) ions – one of the causes of deterioration in battery performance.

Using intelligence gained from this process, Toyota believes essential guidelines can be drawn up to help in the research and development of batteries with improved performance and durability, leading to longer battery life and driving ranges for plug-in hybrid and electric vehicles.

In detail: how the technique works

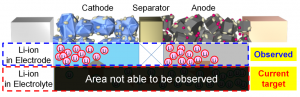

Li-ion batteries use a metal oxide in the cathode, a carbon material in the anode and an organic electrolyte. Lithium ions flow in the electrolyte from the cathode to the anode when the battery is charging, and from the anode to the cathode when the battery is discharging, which results in an electric current flow. Thus, the Li ions play an essential role during battery charging and discharging.

It has been known that Li ion deviation occurs in the electrodes and electrolyte as a result of charging and discharging. It has been believed that such deviation limits the usage area of batteries, one factor that reduces the area in which the maximum performance of the battery can be achieved. When investigating the mechanism of Li ion deviation, however, confirming the behaviour of Li ions in the electrolyte under the same environment and conditions as when it is being used in related products has not been possible using existing techniques.

The two main features of the observation technique that Toyota has developed to help solve this problem are: –

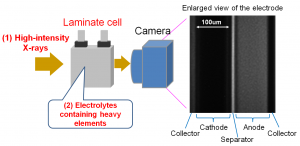

- (1) The Toyota beamline2 in the SPring-83 synchrotron radiation facility, which generates the world’s highest-performance synchrotron radiation, produces high-intensity X-rays that are approximately one billion times more powerful than those generated by X-ray equipment. This makes it possible to create 0.65 micron/pixel high-resolution and 100 ms/frame high-speed measurements.

- (2) In place of the electrolyte with phosphorous that is used in many Li-ion batteries, a new electrolyte with heavy elements is being used instead, thus replacing the phosphorous-containing ions that the Li ions bind to as they move in the electrolyte with heavy element-containing ions. Heavy elements transmit fewer of the X-rays than phosphorous, and the shadows on the images taken after the X-rays pass through are darker. By observing the behaviour of the heavy elements, it is possible to observe the deviation behaviour of the Li ions which are bound to them in the electrolyte.

By using the technique described above, and a battery that is similar to that of related products, such as laminated cell, under the environment and conditions that resemble those of actual battery use, it is possible to observe in real-time, the process of Li ion deviation that occurs in electrolytes during the course of battery charging and discharging. This observational technique was jointly developed by Toyota Central R&D Labs, Inc., Nippon Soken, Inc., and four Japanese universities.4

Going forward, Toyota will observe the behaviour of Li ions caused by differences in the materials and structures of cathodes, anodes, separators, and electrolytes, as well as the differences in battery control. Analysing the mechanisms that cause deterioration of battery performance will lead to R&D that can help to improve the performance and durability of batteries, to bring about longer battery life and longer driving ranges.

1 Techniques for observing laminated cells by using high-intensity X-rays and incorporating heavy elements into an electrolyte (According to Toyota Motor Corporation, as of August 2016)

2 Installed as a special-purpose beamline by Toyota Central R&D Labs, Inc. with the Cooperation of the Institute of Physical and Chemical Research (RIKEN) and the Japan Synchrotron Radiation Research Institute (JASRI).

3 A testing and research facility with the world’s highest performance synchrotron radiation comprehensively operated by RIKEN as the facility owner. Operated and maintained by the Japan Synchrotron Radiation Research Institute (JASRI). SPring-8 stands for Super Photon ring-8 GeV.

4 Hokkaido University, Tohoku University, Kyoto University, and Ritsumeikan University.